|

TTM-1000H

TTM-1000H |

|

|

The tip is heated up by

high frequency current and keeps the soldering

temperature constant. It is ESD safe and

has very low maintenance costs as the tip

only needs to be replaced.

|

|

|

| TTM-1000H |

|

Power

|

AC100V,AC115V,AC220V |

|

Setting temperature

|

200~420°C

|

|

Heat capacity

|

90W

|

|

Output power

|

36VAC. 400KHz

High frequent current

|

|

Temp. consistency

|

±2°C(No load)

|

|

Raising time

|

25sec. (300°C)

|

|

Weight

|

|

Controller

|

2.5kg

|

|

Iron unit

|

0.1kg

|

| Iron

stand |

1.0kg |

|

|

|

|

|

TTM-5000

TTM-5000

|

|

|

Built-in

nitrogen gas generator technology

provides a solution for lead free

soldering. |

|

Quick

temperature recovery and with N2 gas

flow enable soldering without a decrease

in temperature thereby avoiding tip

oxidation. |

|

99%

N2 gas flow to the tip of the soldering

iron via internal cable at 0.5liter

per minute. So, no extra tube is required

for N2 gas flowing. |

|

Motorized wet sponge roller

makes tip cleaning much easier. |

|

| TTM-5000

specification |

|

Power

|

AC100V-115V/AC220-24V |

|

Heater capacity

|

75W (AC24V)

|

| Heater

insulation resistance |

More than 10MΩ(Temperature

raising time)

|

| N2

gas density |

0.5 liter per minutes

/ 99% |

| Size |

129(w)x167(D)x184(H)

mm

|

| Weight |

4kg |

|

|

|

| |

|

|

SSA.SSB

Solder Feeding Unit

SSA.SSB

Solder Feeding Unit |

|

| SSA/SSB

main specification |

|

Power

|

AC100V 50/60Hz |

|

Motor

|

DC motor 5W

|

| Soldering

speed |

13mm/sec~30mm/sec

|

| Soldering

dia. |

Φ0.4mm~2.0mm |

| Weight |

1.5kg

|

|

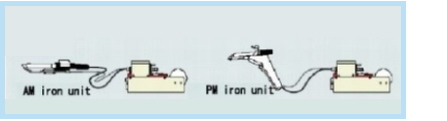

SSA SSA

|

SSA has a built-in motor controller.

The solder can be fed forward or reverse and

can be controlled by an external controller.(PLC

etc.)

SSA has a built-in motor controller.

The solder can be fed forward or reverse and

can be controlled by an external controller.(PLC

etc.)

Forward drive is adjustable with speed controller.

Solder clog and shortage sensor are standard

features.

|

SSB SSB

|

Vari-tap type simple temperature

controller is built-in to detect temperature

without a sensor.

Vari-tap type simple temperature

controller is built-in to detect temperature

without a sensor.

The solder wire feed length is controlled

with a timer.This can be fed by pressing the

trigger on the iron unit. |

|

| |

|