L-CAT-EVO-LASER

L-CAT-EVO-LASER

|

|

|

Laser

Soldering Robot - Solder Wire Feed

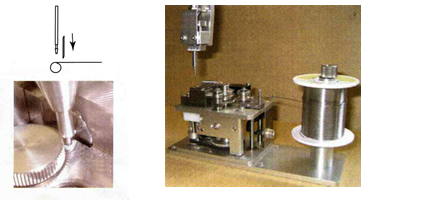

Non-contact soldering can be done while

solder wire is feeding automatically using

4 axes soldering robot and high power LD

(laser diode) laser.

It is much easier to determine the parameters

since the laser power is controlled from

the robot and solder wire feeding position

is precisely adjustable.

Compared to a conventional Laser, this unit

has a longer life time, is more compact

and consumes less power. The unit is highly

efficient and incorporates precise air cooling.

Using an optical fiber to direct the laser

beam, the unit can be easily attached to

other equipment.

|

| Laser

Main Specification |

|

Power

|

Single phase AC100~AC240V |

|

Acceptable solder

wire

|

Φ0.3mm~1.6mm

Select one size

|

|

Laser type

|

Fiber coupling type

LD Laser , Class4

|

|

Laser Generating

|

CW (Continuous power)

|

|

Central wave length

|

808nm±3nm or 980nm±.3nm

|

|

Maximum output

|

20W, 30W, 60W

|

|

Minimum spot

|

Φ0.6mm (Φ0.4mm option)

|

|

Focus distance

|

About 40mm

|

|

Fiber bending radius

|

300mm

|

| Cooling

method |

Air

& Electronic cooling |

| Control

method |

Manual

or External I/O |

| Safety

circuit |

Inter

Lock |

| Optical

fiber (Maintenance parts) |

Whenever

necessary |

| Focus

Lens (Maintenance parts) |

Whenever

necessary |

| LD

laser (Maintenance parts) |

More

than 10,000 hours(Exp.) |

| LD

unit |

200mm(W)x450mm(D)x50mm(H)

|

| Focus

Lens |

Φ31mmx57.4mm(L) |

| Optical

fiber |

3m |

|

|

Laser

Soldering Robot-Solder Pre-Form (ring)

Flux cored solder wire is formed to a ring

shape automatically. Then it is picked up

by a robot and placed on the substrate for

laser soldering. High density connectors/pin

array are perfect candidate for this technology.

|

| 1. |

Forming

solder wire to a ring shape using a

pick pin as a core. |

| 2. |

The solder wire is

fed and cut. |

| 3. |

From the ring shape

around the pin and place onto the lead/component. |

| 4. |

Utilize the laser

to re-flow the fabricated pre-form and

create the solder joint. |

|

| |