|

| |

|

|

|

| |

|

L-CAT-EVO

L-CAT-EVO

|

|

Determinig the optimal soldering

parameters is easy as this specialized

soldering robot (L-CAT EVO) has innovated

featurse and has evoled from proven technology.X

& Y motors with high accuracy rotary

encoders achieve 0.01mm resolution.

All of the cables are installed inside

the Z-axis.Cables will not tangle during

rotation. The program capacity 100 programs

and 100,000 points total to meet various

PCB soldering requirements.The soldering

temperature can be customized inside each

of the 198 soldering profiles to provide

component specific recipes as requieed

by the application.

|

|

L-CAT-EVO

line up

|

|

L-CAT-EVO4330

XY move area

ZR move area |

4 axes

X= 300mm Y= 300mm

Z=60mm R=360° |

|

L-CAT-EVO4430

XY move area

ZR move area |

4

axes

X= 400mm Y= 300mm

Z=60mm R=360° |

|

L-CAT-EVO4540

XY move area

ZR move area |

4

axes

X= 500mm Y= 400mm

Z=60mm R=360° |

|

| |

|

|

|

Moving method:

|

5 phase stepping motor

encoder with X,Y axes |

|

XY Max. speed:

|

750 mm / sec

|

|

Z axis Max. speed:

|

150 mm / sec

|

|

R axis Max. speed

:

|

360° / sec

|

|

Teaching method:

|

Jog key and MDI

|

|

Program :

|

100

|

|

Memory capacity:

|

Maximum 100,000 points

|

|

External I/O :

|

IN: 5 / OUT: 7

|

|

External interface:

|

RS232C

|

|

Resolution :

|

0.01mm

|

|

Repeatability:

|

±0.02mm

|

|

Portable weight:

|

3 Kg

|

|

Weight :

|

50 Kg

|

|

Power consumption:

|

Max330VA including

heater

|

|

|

|

| Number

of parameter |

198

conditions |

| Solder

step |

21

steps (Free combination) |

| Setting

temperature |

TEM

: 0 ~ 500°C |

| Solder

feeding speed |

S+/S-

: 0.1 ~ 50.0 mm / sec. |

| Delay

timer |

TIM

: 0.1 ~ 99.9 sec |

| Iron

up and down |

CY

: ON / OFF |

| Acceptable

solder wire |

Φ0.4mm

~ Φ1.6mm |

| Heater

capacity |

100W |

|

|

|

|

|

J-CAT

Series

J-CAT

Series

|

|

User-friendly robot teaching

is achieved with a large LCD display.

Using the block copy function, many other

points can easily be entered after the first

point is entered (step & repeat).

The coordinates can be entered in JOG key

or MDI (numerical input) mode.The built-in

point job program, sequence control and

palletizing function makes communication

with other machines, equipment and sensor

a simple process.

Nine(9) models are available in a combination

of 3 & 4 axes robot (J-CAT200,J-CAT300,

J-CAT400 and three controllers TERRA, LUNA

and ECHO.

Your application size & requirement

will provide a clear choice of machine configuration.

|

J-CAT

specification: J-CAT

specification: |

|

|

J-CAT-200N |

J-CAT-300N |

J-CAT-400N |

|

X,Y axes moving area

|

200 X 200 mm |

300

x 300 mm |

400

x 400 mm |

|

Z,R axes moving area

|

Z=50mm R=±360°

|

Z=100mm

R=±360° |

Z=100mm

R=±360° |

|

Speed

|

XY axes PTP

|

5~500 mm/sec

|

8~800

mm/sec |

8~800

mm/sec |

|

Z axis PTP

|

2.5~250 mm/sec

|

3.2~320

mm/sec |

3.2~320

mm/sec |

|

R axis PTP

|

6~600° / sec

|

8~800°

/ sec |

8~800°

/ sec |

|

XYZ axesCP |

0.1~500 mm/sec

|

0.1~800

mm/sec |

0.1~800

mm/sec |

| |

J-CAT-200TERRA |

J-CAT-300TERRA |

J-CAT-400TERRA |

| Solder

Parameter |

297

conditions |

297

conditions |

297

conditions |

| |

J-CAT-200LUNA |

J-CAT-300LUNA |

J-CAT-400LUNA |

| Solder

Parameter |

32+LUNA

7conditions |

32+LUNA

7conditions |

32+LUNA

7conditions |

| |

J-CAT-200NEcho |

J-CAT-300NEcho |

J-CATNEcho |

| Solder

Parameter |

32

conditions |

32

conditions |

32

conditions |

|

|

|

|

|

6

axes Articulated Robot

6

axes Articulated Robot

|

|

|

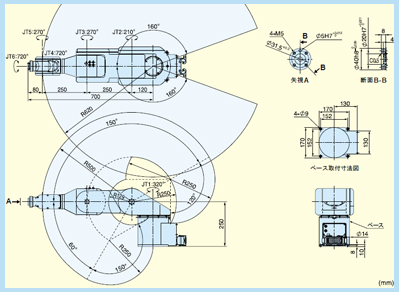

This compact unit offers 6-axis

high function performance to handle PCB's

and components for soldering, component replacement

and automating repetitive tasks.

The robot's main unit weights an easy-to -handle

20 kg and they can even be mounted on the

floor, wall or ceiling. In spite of the small

size, they are equipped with fast accurate

and sturdy 6-axis arms for ensuring high reliability

and precision.

The robot can withstand most operating environments

in the industry.There is no need to worry

about a stop position when the power is turned

off as all six axes have brakes.

|

|

Apollo Seiko/Kawasaki

FS003N |

|

Arm Type |

Articulated |

|

Degrees of Freedom

|

6 Axes |

Axis

Work Envelope

|

Axis |

Max.

Stroke |

Max.

Speed |

| JT1:Arm

rotation |

±160° |

±360°

/S |

| JT2:Arm

out-in |

±150°~-60° |

±250°

/S |

| JT3:Arm

up-down |

±120°~-150° |

±225°

/S |

| JT4:Wrist

swivel |

±360° |

±540°

/S |

| JT5:

Wrist bend |

±135° |

±225°

/S |

| JT6:Wrist

twist |

±360° |

±540°

/S |

| Max.

Reach |

620mm(Distance

from JT1 to JT5) |

| Max.

Payload |

3kg |

| Moment |

JT4:Wrist

swivel |

5.8N.m |

| JT5:

Wrist bend |

5.8N.m |

| JT6:Wrist

twist |

2.9N.m |

| Moment

of Inertia |

JT4:Wrist

swivel |

0.12kg.㎡ |

| JT5:

Wrist bend |

0.12kg.㎡ |

| JT6:Wrist

twist |

0.03kg.㎡ |

| Position

Repeatability |

±0.05mm(At

wrist flange surface) |

| Max.

Linear Speed |

6,000mm/s

(At wrist flange surface) |

| Mass |

20kg

(Excluding option) |

| Body

Color |

Munsell

10GY9/1 equivalent |

| Installation |

Floor,

Ceiling or Shelf mount |

| Environmental |

Ambient

Temperature |

0~45°C |

| Relative

Humidity |

35~85%(No

dew, nor frost allowed) |

| Vibration |

Less

than 0.5G |

| Other |

The

robot installing place should be free

from:

*Inflammable or corrosive liquid or gas

* electric noise interference |

| Option |

Wall

Mounting

(Max.Payload:2kg)

Restriction of motion range

(mechanical):JT1 (45! pitch)

External sensor harness

(4 circuits) |

1

Double solenoid valve

2 Double solenoid valves

1 Single solenoid valve

2Single solenoid valves |

|

Motion

Range & Dimensions Motion

Range & Dimensions

|

|

| |

|

|

|

|

|

|

|

|